Project Successes

Intrastack uses a just-in-time approach to deliveries, eliminating unnecessary travel and transport uses from the process.

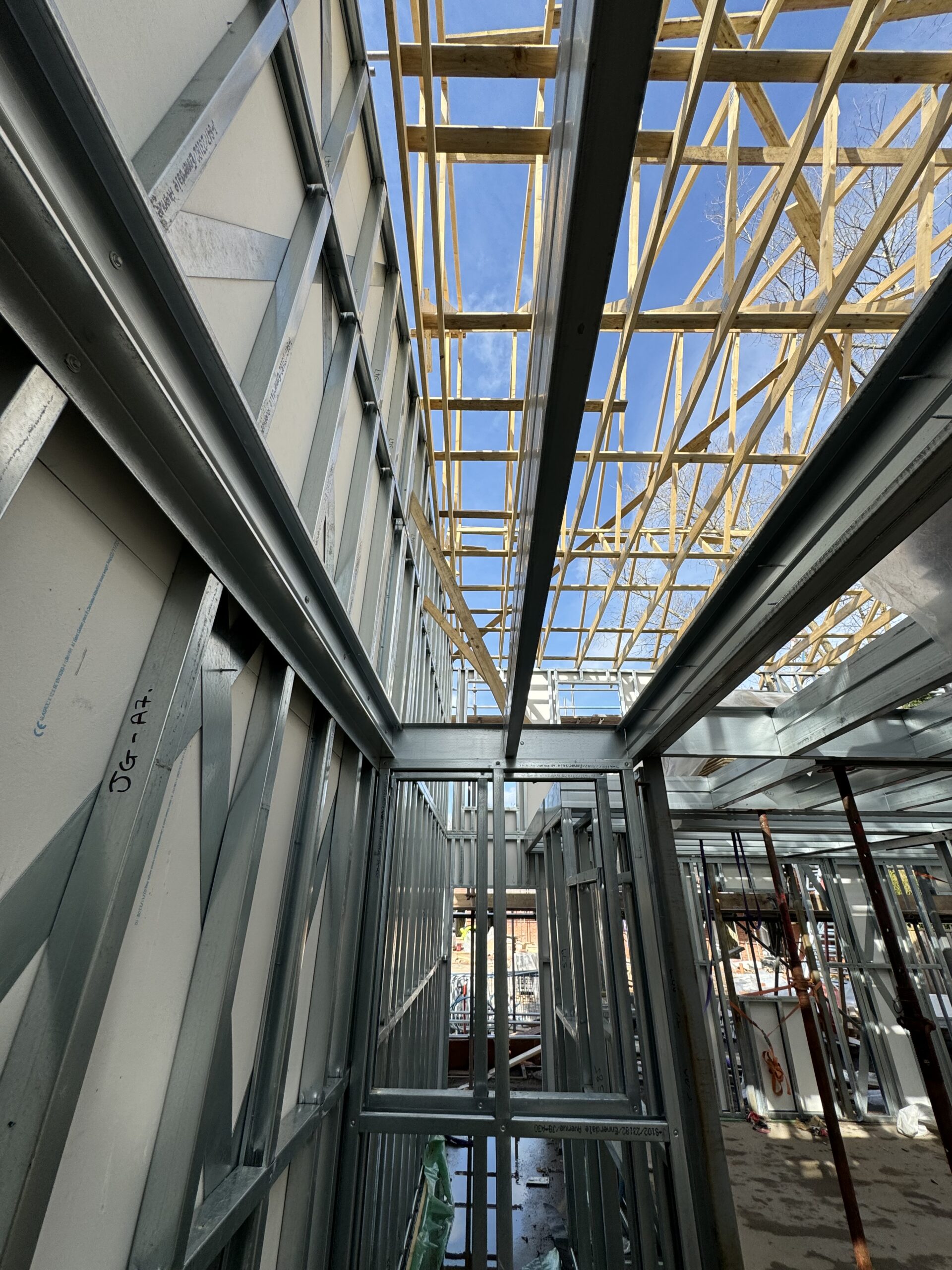

For Ennerdale Avenue, the steel frame panels were delivered to site exactly when they were required by the installation team. This meant the limited space on-site was not an issue for storing materials, as deliveries were only made when the panels were needed and didn’t take up any of the limited storage space.

The costings for the project went as planned, this was made possible as Intrastack was involved from the early stages of the design process. This early involvement also meant the structures were the exact measurements and requirements as agreed and determined before any on-site work took place. As a result, there were limited changes required during the manufacturing process, helping to ensure the project was delivered on budget.

In addition, there was no on-site waste as the build components for the project were accurate within 1mm, because of the exactness of the Intrastack LGSF solution.

The Intrastack low rise housing solution helped to enhance the building performance by ensuring the wall build-ups exceeded the national requirements, which are indicated in the Future Homes Standard consultation document.

The specified and designed U-value for the four semi-detached homes and four cottage flats was in-line with building regulations. By working with partners, both external and sister brands within Saint-Gobain, the homes built at Ennerdale Avenue exceed the required U-values for new dwellings, in turn ensuring energy-efficient homes for the occupants. Intrastack’s solution can be designed to reach U-values as low as 0.13 W/m²K.